Thermal Engineering

Temperature Measurement and Calibration

Students learn how to measure temperatures in different units using various types of temperature sensors. They also learn how to calibrate commonly used temperature sensors, which reveal the important relationship between data quality and instrument calibration.

Saturation Temperature and Pressure

Students learn about the relationship between pressure and the temperature of water, how pressure affects boiling point and how much vapor content exists in a mixture of liquid and vapor.

Thermal Radiation

Students study the laws of heat transfer by radiation through various finishes of the same material. Students also investigate the relationship between radiation and temperature.

Natural and Force Convection

Students study the properties of and the differences between heat transfer caused by natural convection (which does not require the mechanical movement of a liquid or a gas) and forced convection (which requires the mechanical movement of a liquid or a gas). Students also examine different extended surfaces designed to improve heat transfer by convection.

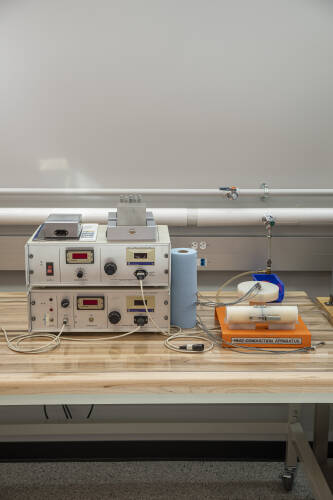

Heat Transfer by Conduction

Students investigate the properties of heat transfer by conduction by studying the thermal conductivity of various materials. Different types of coordinate systems can be used for various material geometry.

Geothermal Trainer

This system teaches students how to harvest geothermal energy for heating and cooling.

Miniature Power Plant

This steam power plant model is equipped with a boiler system, a steam turbine, a pump, and condenser, giving students an opportunity to monitor and control the plant operation and its performance.

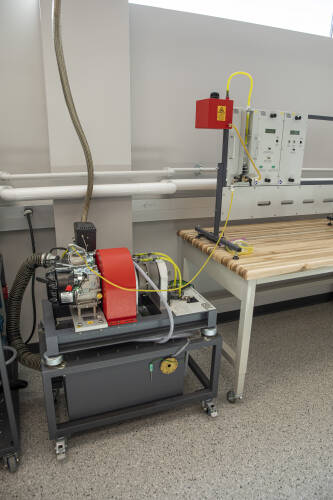

Four-Stroke Internal Combustion Engine

Students learn the inner workings of the most common internal combustion engine designed for motorized land transport. They are used in automobiles, trucks, diesel trains and motorcycles.

Flow Measurement

With this equipment, students will use typical methods to measure the flow of water and will study the relationship between rate of flow and velocity.

Heat Exchanger

Students investigate the performance of different types of heat exchangers used in many industrial applications, such as air conditioning.

Centrifugal Pump

Students study the performance operating centrifugal pumps, which are the most popular and commonly used type of pump for the transfer of fluids.

Center of Pressure

This equipment will help students determine the static force exerted by a fluid on a submerged surface, similar to how a hydraulic dam is influenced by water.

Vapor Compression Refridgeration Cycle

Comprised of a compressor, a condenser, an expansion valve/throttle valve and an evaporator, this equipment teaches students how a refrigerator or a window air conditioning unit works.

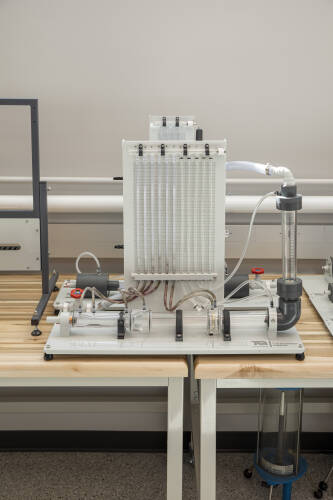

Cooling Tower

Students learn about this essential part of a power plant, which removes heat by spraying water down through the tower to exchange heat with the surrounding air. The cooled water returns back to the power plant for continuous operation.

Fuel Cell Trainer

With this equipment, students learn what comprises a fuel cell and how they work.

Photovoltaic Troubleshooting Station

Students learn a range of solar photovoltaic (PV) operation, maintenance and troubleshooting skills through hands-on experience with real industrial solar PV components.

Wind Tunnel

Students learn about the aerodynamics of vehicles and flying objects with this equipment, which includes a smoke generator to help with visualization.

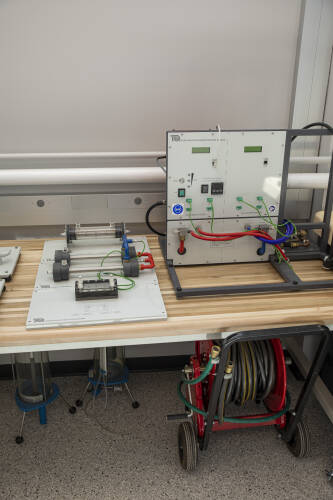

Hydraulic Trainer

Students learn how pneumatic and hydraulic components affect the functions of machines and devices that operate based on hydraulic pressure.