Engineering Design Workshop

Smithy Lathe/Mill Combo

This machine contains lathing and milling capabilities that give students the capability to create products that would require four axes of movement. A bolt, for example, can be made on a regular lathe to produce the head diameter, the shaft and the threads. However, a regular lathe can’t make the cuts needed to make it a hex bolt. This machine can make the eight straight cuts without the need to set up another machine.

Kent Manual Mill

This large milling machine is capable of producing very large and complex products, depending on the user’s skill set. As a manual machine, the student operator will have full control on how it moves in each of its axes and can adjust feed rates as needed. Similar to the combo lathe, this machine comes with an optional 4th axis turning attachment to make even more complex parts.

Baileigh 3 in 1 Machine

This versatile tool is used to shape metal materials into products. For instance, students can make a circular fire pit by using the machine’s sheet metal roller. The binding function can compress metal parts to have specific angles at the joints, Finally, it possesses a large sheer designed to cut sheets of metal.

Plasma Table

This CNC plasma table functions like a laser engraver. The material is fixed in place while the machine blasts plasma onto the chosen metal to replicate the shape/design made by the student. This machine can cut through material from the thickness of regular sheet metal to a few inches thick.

HAAS CNC Lathe

After learning how to use a manual lathe to make a part, students learn how to replicate the same part on this CNC machine. To do so, students use CAD and CAM software programs to draw the part. The finished drawing is output into G-code—coding that instructs the machine what to do to replicate the part. This experience is particularly beneficial for mechanical engineering technology students.

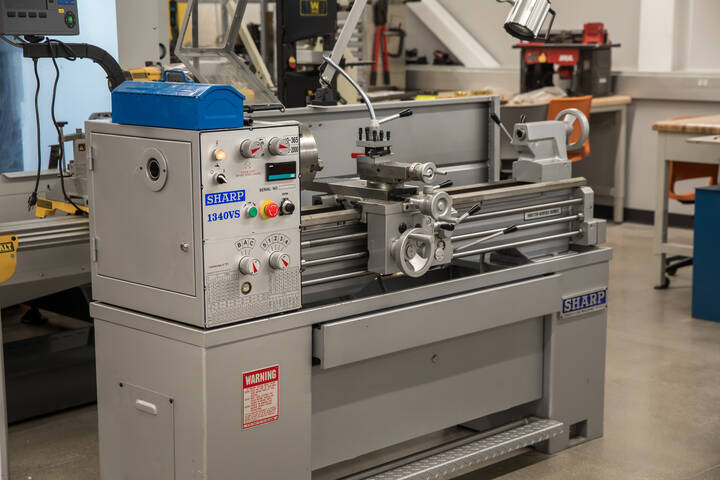

Sharp Manual Lathe

This machine allows student to make products that are circular in nature such as shafts, bolts, doorknobs, etc. It does this by rotating the stock material while the user manually controls the position of the cutting tool. Stock is removed until the desired shape and size is achieved.

HAAS CNC Mill

Because of its functional versatility of this machine, students are able to:

- Experiment with different ways to fix material to a machine bed so it can’t move during production

- Familiarize themselves with different cutting tools and the results they produce on different materials

- Use CAD/CAM software programs to create G-code that enables the machine to produce parts with high accuracy and efficient repeatability

Experiences gained from this machine are particularly beneficial for mechanical engineering technology students.