Additive Manufacturing Lab

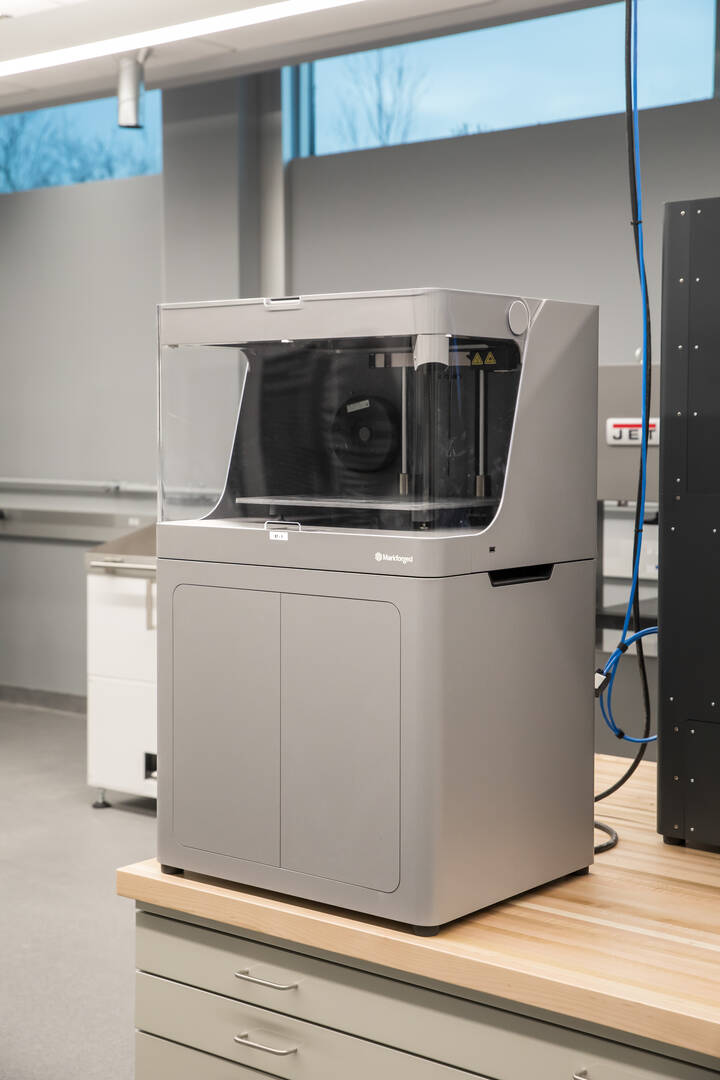

Markforged X7 3D Printer

Students use this machine to fabricate industrial-grade parts or rapid prototyping from a full range of composite materials (carbon-fiber and others) in a process called continuous fiber reinforcement (CFR).

Markforged Metal X 3D Printer

Students use this machine to fabricate complex metal parts from a wide range of metals—including stainless steels, titanium and copper. The technology is called fused filament fabrication (FFF) where metal powder, bound in plastic, is printed a layer at a time into the shape of the part.

Kiln

Students use this kiln to post-treat parts printed by the EOS M 290 3D metal printer (located in the Thermal Sciences Lab). By subjecting the parts to the kiln’s intense heat—a process called stress relief—the parts become less prone to distortion.

Abrasive-Blast Cabinet

Students use this cabinet to post-treat parts printed by the EOS M 290 3D metal printer (located in the Thermal Sciences Lab). Abrasive blasting removes unwanted support material from 3D prints. A process called shot peening smooths surfaces and blends in striation lines generated during 3D printing, which strengthens the part.

Band Saw

Students use this band saw to post-treat parts printed by the EOS M 290 3D metal printer (located in the Thermal Sciences Lab). The saw is used to remove the printed part from the build plate.

Post-Processing Station

Students use this post-processing station, primarily to remove excess material from their polymer 3D-printed parts.

EOS FORMIGA P 110 Velocis 3D Printer

Students use this machine to fabricate industrial-grade parts from a wide array of highly developed polymer materials for additive manufacturing and rapid prototyping.

SHINING 3D EinScan Pro HD Scanner

Students use this equipment to capture accurate, high-resolution scans of 3D objects, which enables the creation of digital 3D models.

Argon Gas Station

Argon gas is used in the controlled atmosphere of the sinter furnace to prevent oxidation and to give printed parts a bright surface finish.

Markforged Sinter Furnace 2

Students use this furnace to post-treat parts printed by the Markforged Metal X 3D printer. In the controlled atmosphere of this furnace, raw parts undergo a process called sintering. The parts are subjected to intense heat which bonds together the metallic particles of the parts and maximizes their strength.

Markforged Wash-1 Washing Station

Students use this machine to post-treat Markforged Metal X 3D-printed parts to remove the metal binding matrix.