World-class Labs

In Indiana Tech’s Talwar College of Engineering and Computer Sciences, we believe in giving students a cutting-edge learning environment furnished with state-of-the-art labs and equipment where they can master their field of study. You’ll jump right in on day one, gaining skills and hands-on experiences that will give you an advantage when it’s time to enter the workforce.

Additive Manufacturing

Here, students will have access to 3D printers that use metals, advanced polymers and composite materials.

Featured Equipment:

- EOS P 110 3D printer

- Markforged Metal X and X7 3D printers

Biomedical Engineering Lab

Located in the Zollner Engineering Center Room Z014, students will learn anatomy with an array of hands-on contemporary teaching tools, including cadavers. Students will also use this lab for developing and validating medical device designs and for the creation of their senior capstone projects.

Featured Equipment:

- Ultrasound machine

- Full-body human specimens

- Anatomage Table Virtual Cadavers

- Medical models

- Large-bone and small-bone battery-powered surgical equipment

- General surgical instrument sets

- Orthopedic surgery-specific instrument sets and implants

Cybersecurity Operations Lab

Part of Indiana Tech’s Center for Cybersecurity, this lab provides students with experience on a variety of security related topics like security information and event management (SIEM) system, vulnerability testing, cyber and CTF competitions, incident handling and building cybersecurity labs for ethical hacking.

Featured Equipment:

- Dell & Lenovo servers

- Netlab host and management servers

- Netlab virtual software

Data Center

Students will get hands-on experience running this data center, which will also house a fully functional network and labs. Here, professors will be able to customize virtual environments to test their students’ knowledge and skills.

The center will feature a VMware-hosted environment, an enhanced digital forensics rack, room for more networking engineering devices, a wireless network and isolated networks for competitions and ethical hacking.

Electrical and Computer Engineering Lab

Students will learn by using oscilloscopes, function generators, DC power supplies, and desktop computers. Electronic components and IC of different types, as well as mutimeters, are also available.

Engineering Innovation Design Center

This lab is utilized by students of any engineering major to 3D print parts as required by various classwork and to enhance their understanding of product development. It is essentially a makerspace for 3D printing but also contains various hand tools and consumables for making products in other mediums.

Engineering Design Workshop

Students will have access to machining and welding equipment, tools and other resources to get hands-on experience with manufacturing processes and fabrication. Here, all engineering students will be able to build projects that are required as part of their coursework.

Featured Equipment:

- TIG, MIG and oxyacetylene welding equipment

- CNC plasma cutter table

- Milling machines (CNC and manual)

- Parts washer

- Sheet metal shear

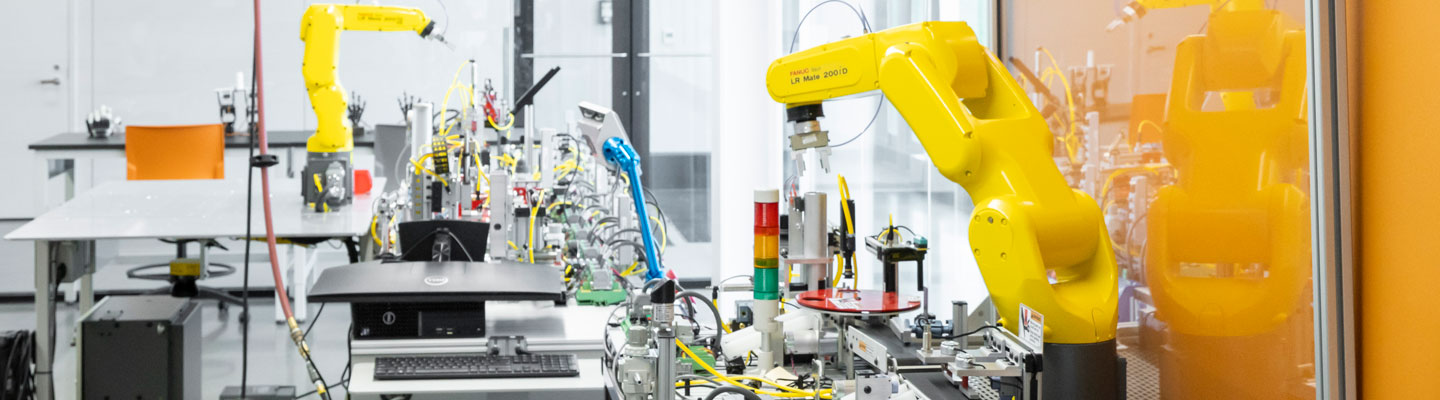

Manufacturing Automation Lab

From state-of-the art machines like collaborative robots to legacy equipment that facilitated the development of current technology, students will have access to the widest range of automation applications in the region.

Featured Equipment:

- APT Connected Smart Manufacturing System

- Universal Robots Robotic Arm, UR3

- Denso Robotic Arm, VP-6242G

- Mitsubishi Robotic Arm, RV-M2

- CNC Jr. CNC Milling Machine

- Intelitek CNC Turning Center

Materials/Solid Mechanics Lab

Featured Equipment

- Shaker table

- Advanced structures set

- Abrasimet 2 abrasive cutter

- Simplimet 2 mounting press

- Nano 2000T grinder/polisher

- Statics torsion package

- IZOD impact tester

- Force table

- Ballistic pendulum

PLC Lab

Equipped with three Amatrol trainers, which are composed of an Allen-Bradley AB5300 L16 processor, a fault insertion system, and a PanelView Plus compact HMI panel, this lab will give students the opportunity to mimic practical industrial temperature control applications, variable speed drive applications, reversing contactor applications and stepper motor control applications.

Power Controls Lab

Students will have access to various types of state-of-the-art, computer-interfaced AC and DC motors, and single- and three-phase transformers. Using a servo drive and braking system, it is possible to easily simulate the performance of various motors (e.g., fans, pumps, compressors, flywheels) under different industrial loads.

Robotics Design Lab

Students will work with robots used in manufacturing processes and other job applications. Some of these job-application robots will include tile runners, which are similar to those used by police forces and NASA.

Featured Equipment:

- Amatrol Smart Factory Industry 4.0 8 Station assembly line

- Amatrol Tabletop Mechatronics Learning System Industry 4.0

Thermal Sciences Lab

Students will use hydraulic and pneumatic equipment to explore fluid mechanics, heat transfer, HVAC (heating, ventilation, and air conditioning) and energy systems.

Featured Equipment:

- Internal combustion engine test bench

- Hydraulic/Pneumatic trainer

- Digital hydraulic bench

- Mass hydraulic bench

- Wind tunnel

Other Labs and Areas

- Network Operations Lab

- 3D Design Lab

- Digital Forensics Lab

- Analytical Organic Chemistry Lab

- Software Engineering Lab

- Information Systems Lab

- Physics Lab